Factors to Consider When Selecting a Kitchen Benchtop

Choosing the right benchtop for your kitchen in New Zealand can be a daunting task due to the various options available in the market. To help you make an informed decision, here are some steps you can follow:

- Determine your budget: Start by determining your budget as benchtops are available at different price points. This will help you narrow down your options and choose the best benchtop within your budget.

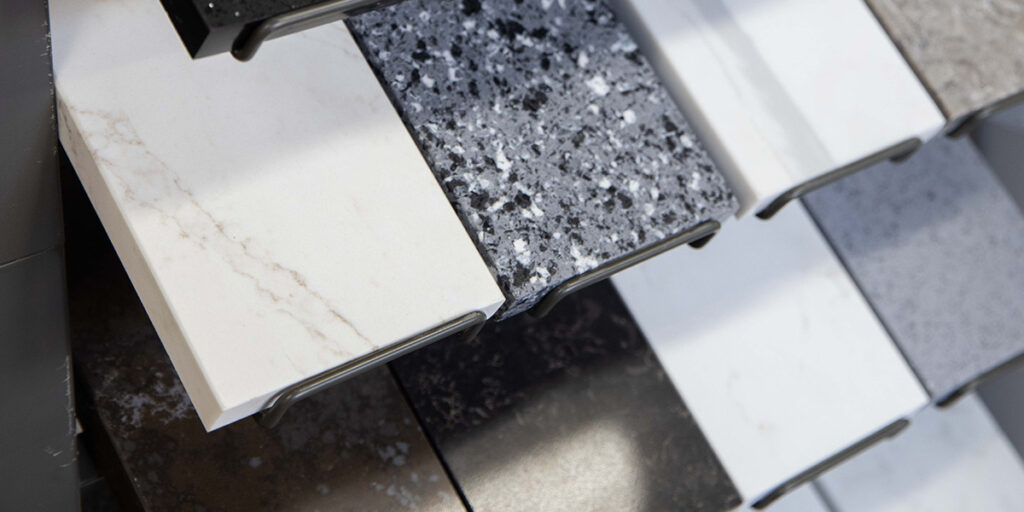

- Consider the material: There are several materials available for benchtops, such as granite, marble, quartz, laminate, and timber. Each material has its own pros and cons, so consider factors like durability, maintenance, and style when choosing the material for your benchtop.

- Assess your kitchen’s style: Your benchtop should complement the style of your kitchen. For a modern kitchen, consider a benchtop with a sleek and minimalist design. For a traditional kitchen, opt for a benchtop with a more classic look.

- Evaluate the maintenance requirements: Different benchtop materials require different levels of maintenance. Natural stone benchtops, like granite, require regular sealing and polishing, while laminate benchtops are relatively low maintenance. Consider your lifestyle and the amount of time you’re willing to spend on maintenance when making your decision.

- Consult with a professional: It’s always a good idea to consult with a professional when choosing a benchtop for your kitchen. They can provide expert advice on the best materials and designs for your specific needs and help you make the right choice.

- Consider the environment: New Zealand’s climate, with plenty of sun and moisture, should be taken into account. Choose a benchtop that can withstand the harsh environment, such as granite, quartz, or stainless steel.

By following these steps, you can choose the right benchtop for your kitchen in New Zealand that meets your budget, style, and functional requirements.

Types of Benchtops Available in New Zealand

Granite

Granite is made up of plutonic rock, which forms in the Earth’s crust as the magma cools underground. It is predominantly composed of quartz and feldspar and is incredibly dense. There are many different quarries around the world, and this gives rise to the variety of colours found in the stone.

Much of the granite available today was formed anywhere from a few million years to over a billion years ago – prior to life on the planet! With a granite benchtop, every slab is unique, and its pattern is formed in nature. You will always have a unique feature in your kitchen! These granite benchtops are cut into slabs after extraction from the quarries.

The size of your benchtop is limited by the size of the slab, and depending on the slab, various lengths are available. In long benchtops, joins may be necessary, and the number of stone slabs required will influence the price.

Kitchen designers try to keep your benchtop within 1 or 2 slabs to keep prices reasonable and the slab colour consistent.

The colour, pattern, and texture variations between slabs, so it’s important to choose the actual slab for your benchtop prior to fabrication, as it may look different from the showroom sample.

Granite may be finished in polished, honed, or leathered finishes. All are professionally sealed with the latest specification sealers for maximum durability and stain resistance.

Honed provides a matte low-sheen finish, reduces reflections, and is easy to maintain.

Polished surfaces are smooth and shiny, easy to maintain, and look spectacular!

Leathered enhances its natural appearance as the surface mimics that of natural stone in its raw state.

Granite can be porous and may stain if untreated. Granite can also harbour bacteria if not finished properly, so it pays to choose your granite from a reputable fabricator who will ensure its finish and appearance, and installation is completed to NZ industry standards.

Kitchen cabinet makers also must ensure the cabinetry structure (and flooring substrate) can support the weight of granite, and if access to the kitchen is other than ground level, a Hiab or crane may be required.

Again, granite must be installed on a solid base that will not move over time, as granite can be prone to cracking and chipping. Care must be taken with the preparation design and installation of the granite. It is an expensive product that requires skilled fabrication and installation.

The cost of granite varies with the region it is quarried and shipped from. Granite is a luxuriously natural product, and for those who want their kitchen to feature a natural stone top created centuries ago, granite is the right choice for your new kitchen!

Concrete

Industrial and edgy concrete benchtops are a hit with many consumers! Concrete benchtops are a mixture of cement, aggregates, and water.

The benchtop is wet cast in place, so it can conform to various shapes. Often, concrete benchtop fabricators will use glass fibre-reinforced concrete for benchtops due to its stronger and more durable properties.

Concrete benchtops are great for a more industrial-edge aesthetic. Polished aggregates can be showcased, and additional features can be added to the stone for effect.

Concrete is porous and needs to be sealed with a combination of industry-specific sealers for benchtop use.

Like granites, concrete can chip, crack, and scratch over time. Depending on the aesthetic of your kitchen, some staining and a patina of scratches can develop over time, giving a lived-in natural edge. (Rounded edges on your stone benchtop may provide some protection from chipping).

Concrete is resistant to heat, but it is recommended to avoid placing very hot objects directly on the surface. The use of breadboards and other heat-resistant materials is advised.

Again, concrete benchtops are best supplied by experienced fabricators who can ensure that the support and structure of the cabinetry and top minimize the chances of cracking and chipping.

Your cabinet maker needs to work closely with the concrete fabricator to provide sufficient support for the weight of the top, and reinforcements should be in place near sinks, hobs, or any other cut-outs.

Ultra-compact surfaces

These tops are sometimes referred to as porcelain or ceramic benchtops and are relatively new to the kitchen industry in New Zealand.

Some say these ultra-compact benchtops are the perfect solution for a maintenance-free benchtop!

These ultra-compact surfaces, such as Dekton or Caesarstone Porcelain, Florim, Neolith, Ascale, and Laminam, are manufactured by putting the raw materials of glass, porcelain, and quartz under extreme heat and pressure, a process called sintered particle technology.

This process creates an extremely hard surface that has superior strength and durability, is scratch, stain, and heat resistant, non-porous, with consistent colours and patterns between slabs, and is fade-resistant and suitable for indoors and outdoors!

Wow! This may be the perfect material for benchtops!

However, the cost is still a factor at this stage. These ultra-compact benchtops are completely nonporous, making them low maintenance and easy to clean!

Used for kitchen benchtops, vanity tops, reception/bar counters, splashbacks, and upstands. Ultra-compact surfaces can come in polished, honed, and textured finishes depending on the chosen colour.

To read more about ultra-compact surfaces, please click the link:

https://www.cosentino.com/en-nz/dekton/worktops/

https://www.caesarstone.com.au/caesarstone-porcelain/

Ultra-compact surfaces are becoming very popular in the NZ market for their wide range of advantages over other materials. However, the downside is cost.

Stainless Steel

Stainless steel can be used for a wide variety of purposes, including kitchen splashbacks and benchtops, due to its hard-wearing features.

Versatility, durability, ease of maintenance, hygiene, and easy care make it a popular choice for commercial kitchens.

It comes in a variety of finishes and patterns.

The process of making stainless steel begins with extracting chromite (an iron chromium oxide) from underground mines. It is then crushed and melted in a furnace with other materials such as iron ore, magnesium, Nichol, and chromium to give it its properties of strength, rigidity, stain and chemical resistance, non-corrosiveness, and rustproofing.

Stainless steel can also be recycled. The stainless steel sheet is typically glued to timber or a plywood base to form a benchtop (the base adds strength and allows a substrate to attach to the cabinetry).

Usually, 304-grade stainless steel with a thickness of 1.5mm is used in the kitchen industry. Stainless steel can be fabricated into many shapes without seams and polished to a high sheen.

Stainless steel is in the mid to high price bracket and is ideal for industrial-look kitchens.

It is important to source your stainless-steel benchtop from a reputable supplier, and it is wise to have the benchtop supplier template, deliver, and install your new benchtop to avoid scratches, dents, and improper fitting.

Stainless steel is a popular choice and is often combined with other surfaces throughout the kitchen for an industrial look, pleasant texture, and variety.

The downsides are that it scratches and can dent relatively easily, the cost is a factor, and it must be well maintained and looked after to retain its good looks and shine.

Timber – Solid Wood, Finger-jointed, and Bamboo

Solid wood benchtops give a uniquely bespoke and warm vibe to a kitchen. Often used to achieve a country or traditional kitchen look, these tops are fabricated from rough-sawn timber sources and can be shaped into various shapes, lengths, and thicknesses.

These benchtops are sealed with high-quality resin, which protects them from chemicals and stains and makes them heat resistant. However, solid wood tops should be protected from high heat and rough surfaces.

While most timbers used are robust, they are still prone to dents, chips, and impacts. Most timber benchtops can be repaired on-site by qualified wood smiths.

Other finishes for solid timber may include an oiled finish for a natural look or a two-pack lacquer for the ultimate hard-wearing, high-gloss surface.

Finger-jointed timber benchtops involve laminating long strips of timber together to form larger lengths of up to 5 meters and a variety of thicknesses, making them a cost-effective option. They also require sealing to protect them from chemical stains, water, and dents.

Eco Bamboo benchtops are a very economical alternative, offering the warmth of a timber look without the cost.

Bamboo is also a renewable source, making it an environmentally friendly option.

The downside is that bamboo is not water or stain-resistant and requires preparation and regular sealing to protect it from moisture. Bamboo is also not heat resistant, so the use of breadboards is recommended.

Preparation and sealing with good-quality lacquer, oil, or polyurethane are recommended to protect the wood from moisture penetrating the bamboo core.

Joins on bamboo benchtops may be more visible due to the pattern direction. Bamboo tops need to be handled and stored with care, as timber is subject to swelling and movement.

To learn more, click this link: https://woodsmiths.nz/

Marble

Last but by no means least!

Marble benchtops are natural stone known for their timeless style, and this luxurious surface has been in use for thousands of years.

Marble is made up of metamorphic rock that forms when limestone is subjected to heat and pressure. It is primarily composed of the mineral calcite and often contains other minerals such as clay minerals, micas, quartz, pyrite, iron oxides, and graphite. As marble is a naturally occurring stone, it feels cool to the touch and does not conduct heat.

Each slab has different patterns, and it is recommended to inspect the slab for your kitchen before fabrication to ensure the colour pattern matches the samples you have worked with.

Unfortunately, marble is not resistant to acids like red wine, citrus, and berries, so care must be taken with the sealant of these tops.

All-natural stones, like marble, are porous and therefore need to be resealed yearly. Marble is a softer stone and is prone to etching and scratching, so care must be taken with its surface. Using a microfiber cloth is recommended to prevent inadvertent scratches to the surface.

Marble comes in different finishes:

- Polished Finish – High sheen

- Honed Finish – Matt to satin

- Leathered Finish – Textured

While marble may not be the most durable surface for use as a kitchen benchtop, the high maintenance is well outweighed by the beauty and romance of running your hand and eye over this luxurious product every morning!

Kitchen countertops are a vast subject, and by clicking on some of the links, you can gain more in-depth product knowledge.

However, a good designer should be able to explain the pros and cons of all the products on the market suitable for benchtops and recommend the surface that meets your aspirations and goals for the look and use of your new kitchen!

Call Kitchens R Us today to book your free kitchen consultation. We specialize in top-quality kitchen design ideas, manufacture, and installation services for kitchens, wardrobes, and custom cabinetry. We are your locally owned and operated kitchen specialists. Make an appointment today, and our friendly team will guide you through your new project!